Fracking Part 2

Environmental Hydraulic Fracturing “Fracking” Concerns

Whether you have seen the documentary movie “GasLand” or not, this picture is sure to spark interest in the environmental safety concerning Fracking and local water supplies.

This is a picture from a resident of Dimrock, Pennsylvania, who was able to light his tap on fire due to hydraulic fracturing that occurs nearby.

In last week’s post we discussed the process by which Hydraulic Fracturing occurs. As a follow up article, this week we will be exploring the environmental concerns regarding the “fracking” process and its impacts on water tables, water supplies & waste water management.

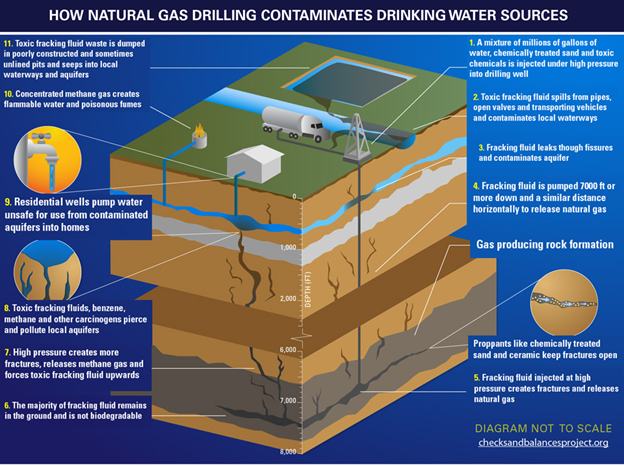

The Diagram below depicts the systemic process of how local water tables, which supply drinking water for local residents, can become contaminated due to the Fracking process. This diagram attempts to prove, that although the fracking takes places 7,000-10,000 feet below most water tables, the fractures created will spread thousands and thousands of feet upward to contaminate the water supply. Using logic, one must assume that this is a highly unlikely possibility, but non the less a possibility. The four most common/likely ways the water can become contaminated are as follows

1) Derrick -The natural gas process involves drilling 5,000 feet or more down and a comparable distance horizontally. The majority of the drilling liquid remains in the ground and is not biodegradable.

2) Well Castings - If the well casing that penetrates through the aquifer is not well sealed, chemicals can leak in to the aquifer.

3) Fractured Shale – To release the gas from underground, millions of gallons of water, sand and proprietary chemicals are injected, under high pressure, into the well. The pressure fractures the shale and props open fissures that enable natural gas to flow more freely out of the well. These fissures may allow the chemicals to enter the water system. In addition, recent reports suggest that radiation in the ground is contaminating the fracking fluid. This radiation has been showing up in drinking water.

4) Surface Contamination - The gas comes up wet in produced water and has to be separated from the wastewater on the surface. Only 30-50% of the water is typically recovered from a well. This wastewater can be highly toxic. Holding ponds, and handling mishaps can release this toxic brew into the environment. For some examples, see the video below about residents in Pennsylvania and the impact of fracking on their water systems. Surface evaporation of VOCs coming into contact with diesel exhaust from trucks and generators at the well site, can produce ground level ozone. Ozone plumes can travel up to 250 miles.

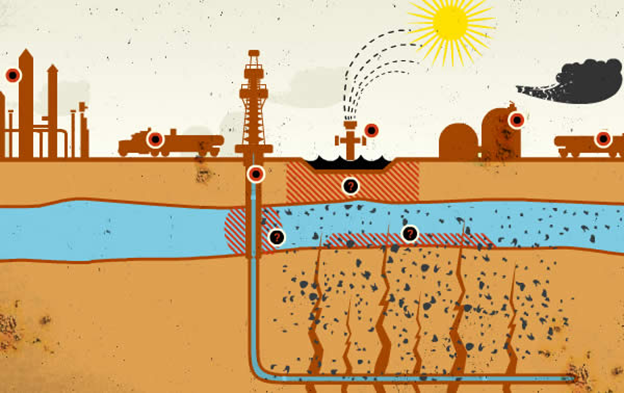

Another diagram skewed to show how fractures can seep into local water aquifers. An interactive version is available at GasLandTheMovie.com.

Government Oversight?

In 2005, the Bush/ Cheney Energy Bill exempted natural gas drilling from the Safe Drinking Water Act. It exempts companies from disclosing the chemicals used during hydraulic fracturing. Essentially, the provision took the Environmental Protection Agency (EPA) off the job. It is now commonly referred to as the Halliburton Loophole.

The FRAC Act (Fracturing Responsibility and Awareness to Chemical Act) is a House bill intended to repeal the Halliburton Loophole and to require the natural gas industry to disclose the chemicals they use.

During the last Congress, the Committee launched an investigation into the practice of hydraulic fracturing in the United States, asking the leading oil and gas service companies to disclose information on the products used in this process between 2005 and 2009.

The Democratic Committee staff analyzed the data provided by the companies about their practices, finding that:

- The 14 leading oil and gas service companies used more than 780 million gallons of hydraulic fracturing products, not including water added at the well site. Overall, the companies used more than 2,500 hydraulic fracturing products containing 750 different chemicals and other components.

- The components used in the hydraulic fracturing products ranged from generally harmless and common substances, such as salt and citric acid, to extremely toxic substances, such as benzene and lead. Some companies even used instant coffee and walnut hulls in their fracturing fluids.

- Between 2005 and 2009, the oil and gas service companies used hydraulic fracturing products containing 29 chemicals that are known or possible human carcinogens, regulated under the Safe Drinking Water Act (SDWA) for their risks to human health, or listed as hazardous air pollutants under the Clean Air Act.

- The BTEX compounds – benzene, toluene, xylene, and ethylbenzene – are SDWA contaminants and hazardous air pollutants. Benzene also is a known human carcinogen. The hydraulic fracturing companies injected 11.4 million gallons of products containing at least one BTEX chemical over the five-year period.

- Methanol, which was used in 342 hydraulic fracturing products, was the most widely used chemical between 2005 and 2009. The substance is a hazardous air pollutant and is on the candidate list for potential regulation under SDWA. Isopropyl alcohol, 2-butoxyethanol, and ethylene glycol were the other most widely used chemicals.

- Many of the hydraulic fracturing fluids contain chemical components that are listed as “proprietary” or “trade secret.” The companies used 94 million gallons of 279 products that contained at least one chemical or component that the manufacturers deemed proprietary or a trade secret. In many instances, the oil and gas service companies were unable to identify these “proprietary” chemicals, suggesting that the companies are injecting fluids containing chemicals that they themselves cannot identify.

Waste Water Management?

Currently the majority of the thousands, if not millions, of gallons of waste water are pumped back in the wells. These chemicals and VOC’s (volatile organic compounds (VOCs) such as benzene, toluene, ethylbenzene and xylene) are not biodegradable. Currently the Western U.S is experiencing a drought and one can reasonable assume that given the amount of water used in the fracking process, recovering as much water as possible is quite necessary.

Resources

1) Gas Tap – Gaslandthemovie.com

2) “how natural gas drilling contaminates drinking water sources” -http://www.greenpeace.org/usa/en/campaigns/global-warming-and-energy/The-Problem/fracking/Fracking-Diagram/

3) http://8020vision.com/2011/04/17/congress-releases-report-on-toxic-chemicals-used-in-fracking/ - Congress Releases Report on Toxic Chemicals Used In Frackingby Jay Kimball on 17 April 2011